The MP-HT “dirt-in-bag” system

Discover the MP-HT "Dirty in Bag" system which facilitates the work of emptying the sweeper by avoiding contact with dust for the operators.

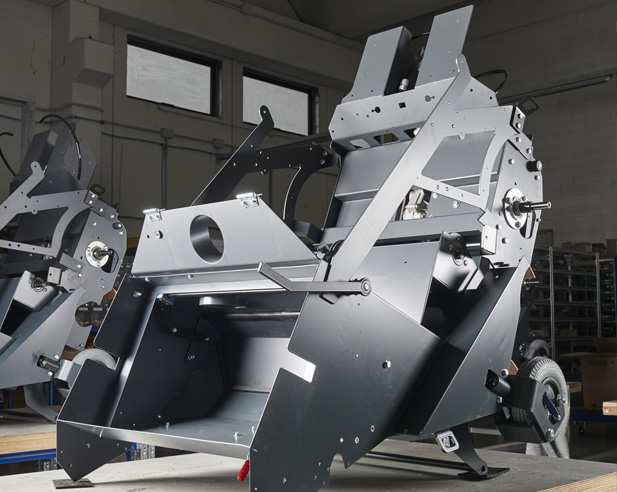

Read the articleThe frame is the supporting structure of any machine and is an essential component for any means of transport, operating machinery, or simple machine tool. To build a solid machine, a resilient frame is essential.

For this reason, at MP-HT, we've chosen to build all our sweeper frames in metal, avoiding the need to resort to rotational plastic moulding.

Manufacturers often resort to plastic frames made with rotational moulding in an effort to reduce production costs. This choice allows the series production of a large number of frames in very little time.

The initial cost of sweepers produced using this method is certainly inferior, but so too is the structural sturdiness and mechanical resistance to different types of stresses.In the long-term, the sweeper will need more maintenance and break more easily.

Moreover, in case of a failure, a rotationally moulded plastic frame doesn’t allow changes or repairs if it breaks. If there’s a fault, the sweeper will be more difficult to repair and will probably no longer be of use.

The choice of primary materials is the first step in building solid, long-lasting machines.

The north-eastern part of Italy where our sweepers are manufactured is renowned for its metalworking industry. We are able to rely on a solid network of companies, trusted suppliers from which we choose only the best components and materials.

Building our sweepers with metal frames offers two key advantages:

Steel, in addition to being a highly resistant material, is also very ductile. When assembling the machine, the metal frame allows us to make changes and reinforce various parts of the machine subject to particular stresses in certain situations. The metal frame allows us to customise the sweepers in order to adapt the machine to specific client needs, thus ensuring the comfort of those who go on to use it.

We were able to satisfy a company’s request to adapt the machine because the person who would use it had a hip problem, and therefore would have found it difficult to climb up. We responded by inserting a support base in the machine frame, allowing the operator to climb up with ease. This would not have been possible with a plastic frame, because once moulded it couldn’t have been drilled to insert additional supports, or modified in any way, or else it would have broken.

The steel used in the frame, which is 100% recyclable, is a fundamental component of our MP-HT sweepers. Steel can be recycled indefinitely without losing its properties or characteristics, making it one of the most sustainable and efficient materials for reuse.

In addition to the steel, almost all other parts of the sweepers can also be recovered and recycled, resulting in a sweeper that is 95% recyclable. This provides a significant advantage when it comes time to dispose of the sweeper.

This is also a key aspect for those of us involved in cleaning, because recycling:

We design our machines with the user in mind. The MP-HT sweepers prioritise the health and safety of operators, being designed to be intuitive, easy to manage, and maintain. This allows them to be used autonomously by non-specialised personnel without the need for licences.